Your specialist for 3D printing with polypropylene (PP)

Products for 3D Printing with Polypropylene (PP)

Our innovative products enable trouble-free and high-quality 3D printing with PP

Our 3D printing service with polypropylene (PP)

Realize your 3D-printing ideas jointly with our specialists

Advantages of polypropylene

Due to the low density of PP it is perfectly suited for the fabrication of lightweight 3D printed products.

PP is a sustainable material because it is fully recyclable.

3D-printed products made of PP withstand mechanical stress very well, as PP has a high breaking strength.

3D printed PP products can be tailored to the requirements of a wide variety of applications due to the semi-flexibility of PP.

PP is perfectly suited for applications in contact with almost all chemicals and solvents as a result of its outstanding chemical resistance.

Polypropylene components are optically appealing and show a high surface quality.

Polypropylene can be used in contact with food and is food-safe.

Products made of PP are dishwasher safe and can be easily cleaned.

Polypropylene is highly suited for contact with water. PP is not moisture sensitive and PP filaments has not to be dried prior to 3D printing.

Products made of PP can be prepared in different colors by using colored filaments.

3D printed parts made of ‘P-fialment 721 natural’ are certificated according DIN EN ISO 10993-5 for biological safety and therefore skin-friendly.

With ‘P-support 279’ the first breakaway support material especially developed for polypropylene is now available.

Do you have any of the following problems?

Are you looking for

a 3D printing material with

a broad property profile?

Do the 3D printing materials currently available on the market not meet your requirements?

Are you looking for 3D printed products that can be used intechnical applications?

Did your 3D-printed components not withstand the required mechanical loads in the past?

Were your previously used 3D printing materials not suitable for medical engineering products?

Do you have

experience with 3D printing

of polypropylene (PP)?

You would like to print high-quality componentsmade of PP. Have you not yet achieved your required quality?

Have you already had poor experiencewith the printability of PP in extrusion-based 3D printing?

Do your 3D printed parts show high warpage and you are not happy with your results?

Did the poor adhesion of printed PP parts to the 3D printing build surface result in warpage or lift off of the edges?

Why PPprint?

Specialization

The PPprint GmbH concentrates exclusively on polypropylene as the material for extrusion-based additive manufacturing. The company offers products for successfully 3D printing of PP for industrial applications and consumer use.. The specialization on PP enables PPprint to develop, manufacture and sell products and services of the highest quality. Based on the profound understanding of the material polypropylene and extrusion-based 3D printing processes, PPprint offers its customers the complete package, from products specially developed for 3D printing of PP to 3D printing services on a contract basis.

Know-How

The interdisciplinary team of five founders has expertise in a wide range of industries. The PPprint GmbH can fall back on decades of experience in research with polyolefins, especially polypropylene. Resultierend auf den Ergebnissen der anwendungsbezogenen Grundlagenforschung, konnte die PPprint GmbH dabei ein für den 3D-Druck optimiertes Produktportfolio entwickeln. Des Weiteren besitzt das Entwicklerteam breitgefächertes Know-How in der praktischen Umsetzung von Produkt-innovationen in den unterschiedlichsten Industriezweigen.

Customer support

With its target-oriented support, PPprint GmbH offers its customers the possibility to realize 3D printing with polypropylene in various ways into development and production processes. In doing so, the company uses its expertise as a material developer and3D printing expertto support its customers in specific applications. The experience in the development of PP products combined with the 3D printing knowledge enable the development and implementation of constructive solution concepts. PPprint offers products not only as merchandise, but on top innovative solutions and individual support for their customers.

Print service and 3D printing training

PPprint offers for the extrusion-based 3D printing of PP all key elements under one roof. The PPprint team offers on a contract basis to create your 3D models, to process the data into 3D printable files, and to manufacture final 3D printed polypropylene products. The in-house 3D printing factory can also produce prototypes, development test series, and low volume production.

In addition, PPprint GmbH supports its customers with training courses on all aspects of 3D printing with PP. Please ask for your individual training via our contact form.

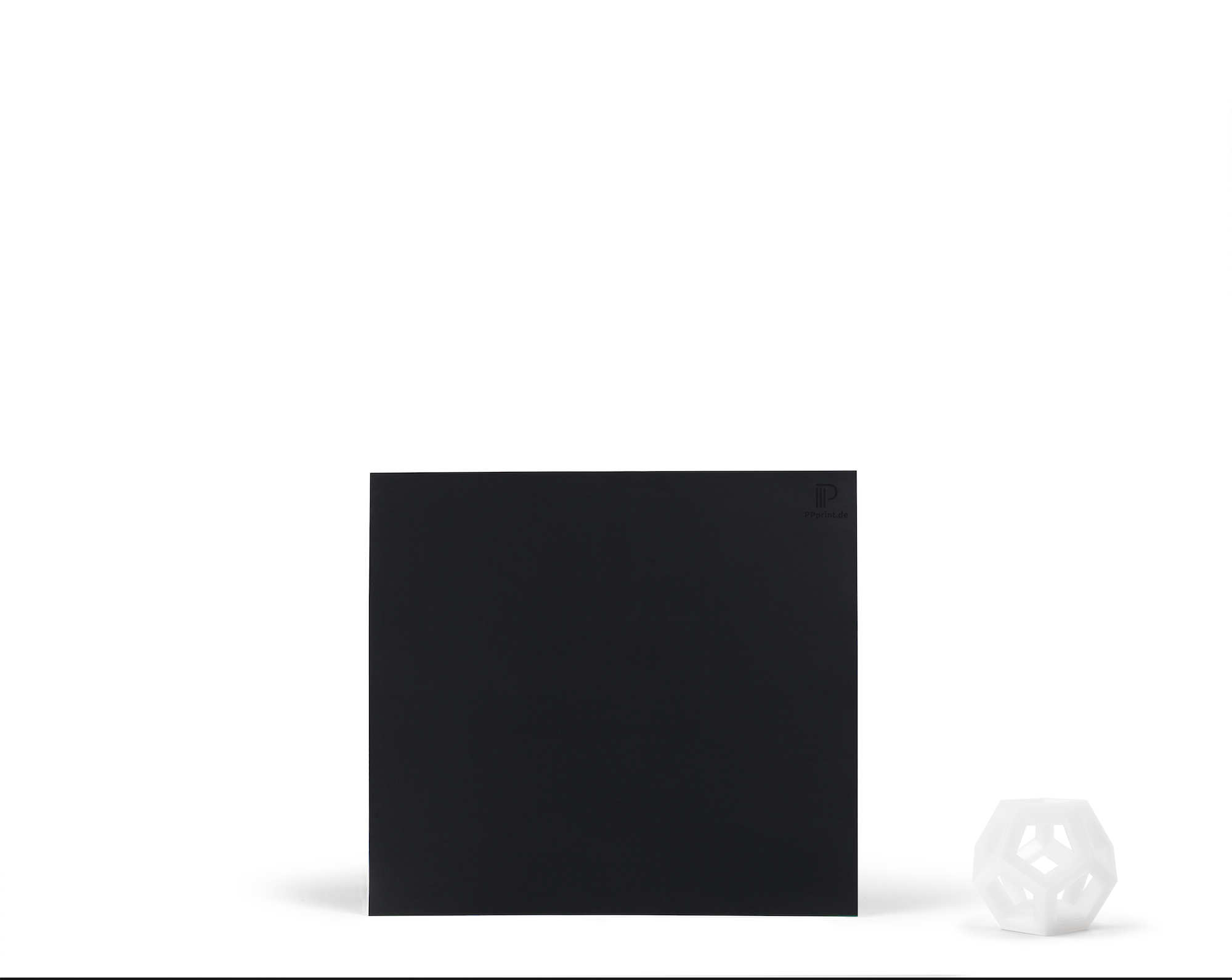

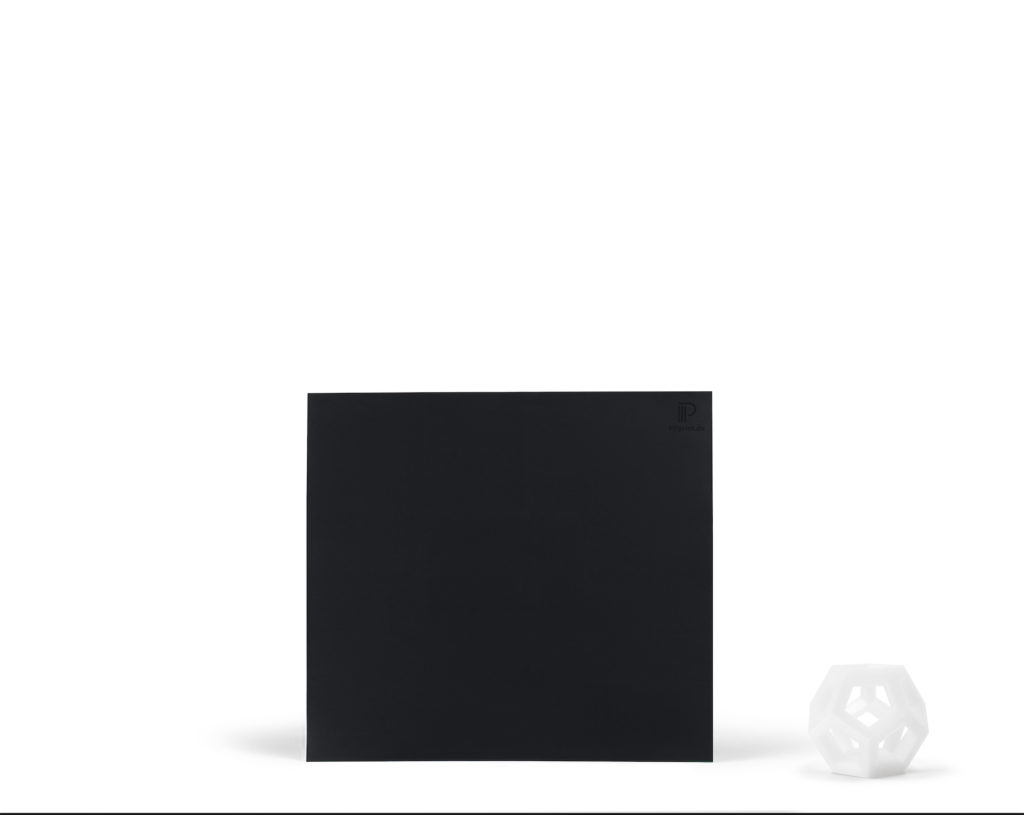

Our innovative 3D printing build surface for PP

P-surface 141

Our patent-pending 3D printing build surface P-surface 141 enables smooth 3D printing of high quality polypropylene parts.

Characteristics

- compatible with all major 3D printers on the market

- available in customize specific sizes

- strong adherence to PP parts counteracts warping

- significant warpage reduction in PP parts

- also suitable for other PP filaments

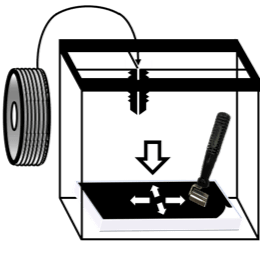

- easy part removal after heating to 100 °C

- very long product lifetime, specially when using the P-Cleaner 298

- also suitable for other common 3D printing materials such as ABS, PLA, TPU, and many more

- Even heat transfer

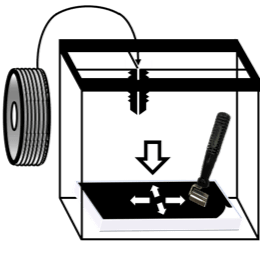

3D printing with P-surface 141

This is how the successful 3D printing of polypropylene succeeds with our products

Frequently asked questions

We are currently in the process of setting up an FAQ for you, in order to provide you with even more assistance in 3D printing with PP.

The most important information about 3D printing with our products can be found on our information flyer. .

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lor separat existentie es un myth. Por scientie, musica, sport etc, litot Europa usa li sam vocabular. Li lingues differe solmen in li grammatica, li pronunciation e li plu commun vocabules. Omnicos directe al desirabilite de un nov lingua franca: On refusa continuar payar custosi traductores. At solmen va esser necessi far uniform grammatica, pronunciation e plu sommun paroles.

Your question could not be answered yet?

Please contact us!

Our material innovations

P-filament 721

Designed specifically for extrusion-based 3D printing, P-filament 721enables manufacturing of industrial products with an outstanding property profiles.

Characteristics

- compatible with all major 3D printers

- low warpage and reduced shrinkage

- optimized layer adhesion

- available in the diameters 1.75mm and 2.85mm

- individually colorable

- combines all the above mentioned advantages of polypropylene and has an excellent property profile

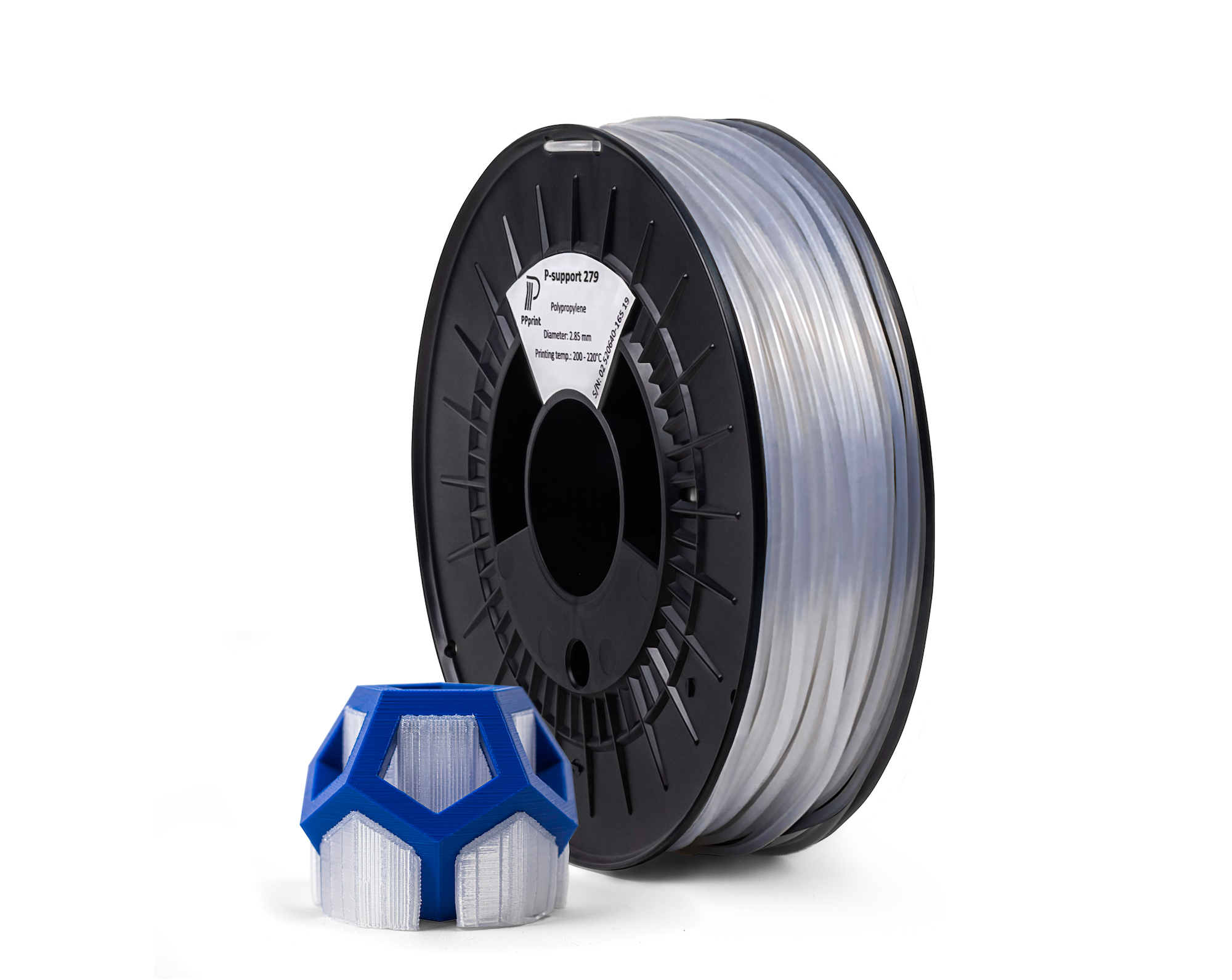

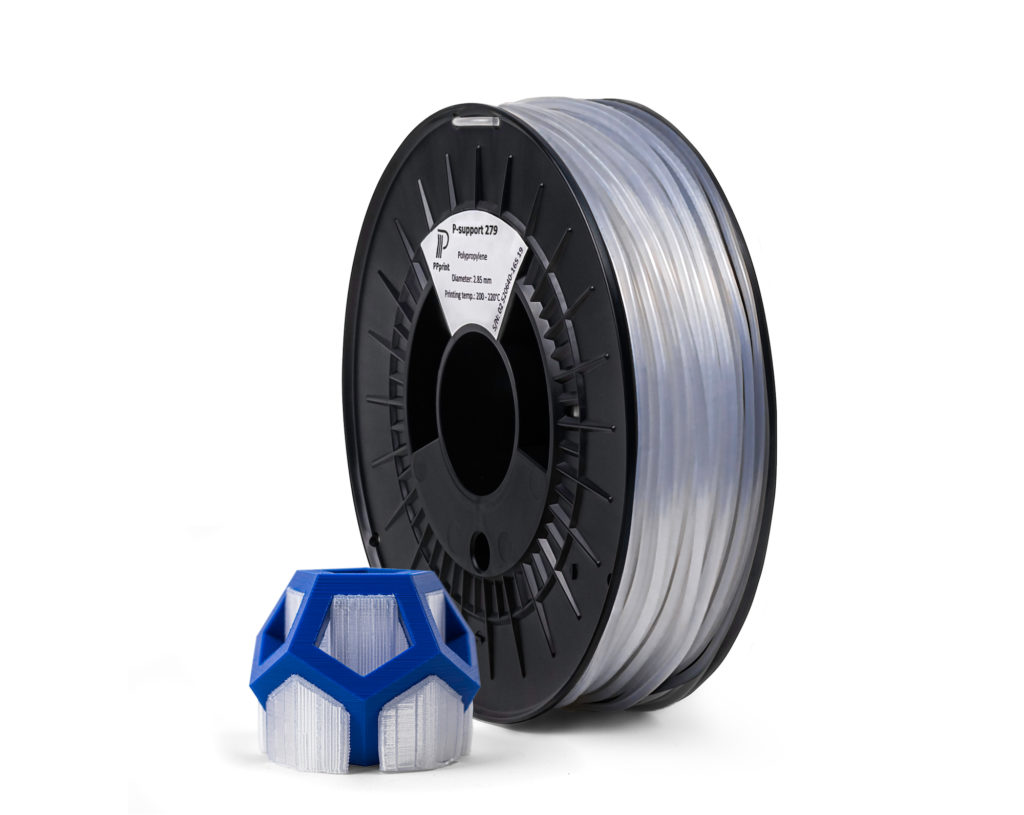

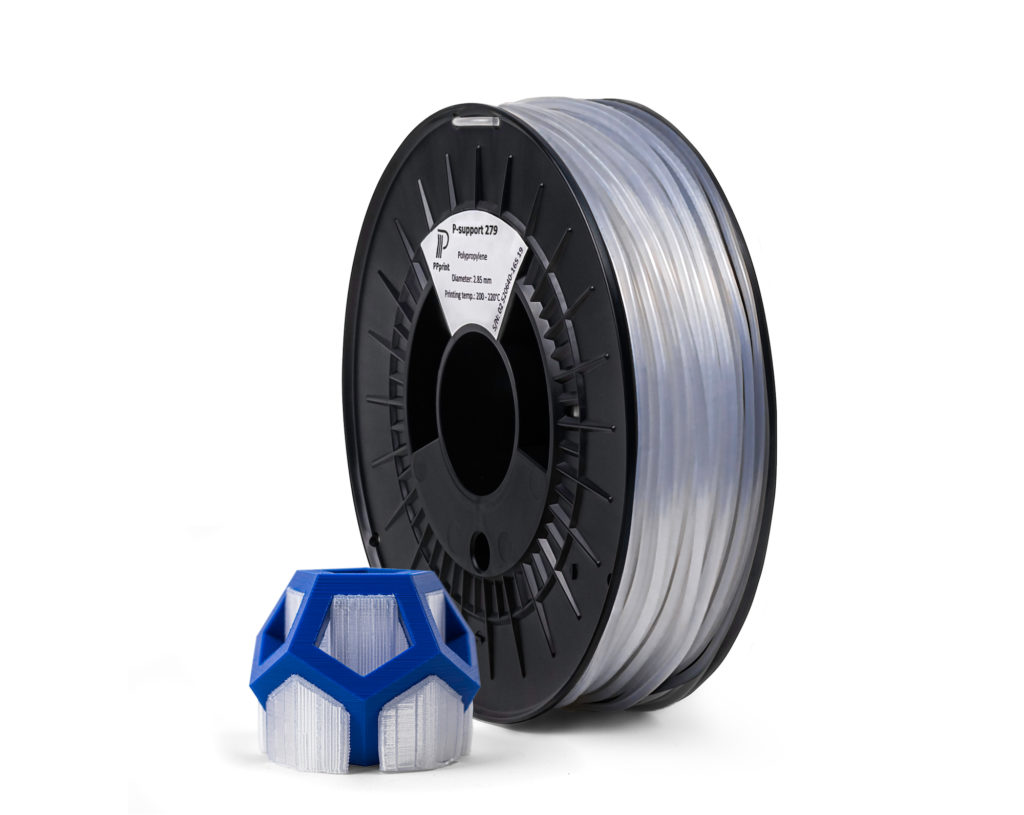

P-support 279

With the world’s first breakaway support material, P-support 279, specially developed for polypropylene you can create more detailed geometric shapes with overhangs and openings.

Characteristics

- breakaway support material

- no production of aqueous or solvent polymer waste

- no post-processing required

- suitable for printing rafts

- high stiffness and low warpage

- excellent adherence to PP and P-surface 141

- easy removal after heating to 100 °C

P-pellets 310

P-pellets 310, specially developed for Fused Granular Fabrication (FGF), enable reliable 3D printing of high-quality polypropylene parts.

Characteristics

- suitable for common pellets-processing 3D printers

- available in quantities starting from 1kg

- optimized for extrusion-based 3D printing

- combines all the above mentioned advantages of polypropylene and has an excellent property profile

Our cooperation partners

Contact us here!

Our areas of application

Polypropylene (PP) is ideally suited as a material for technical and medical applications due to its balanced property profile. The combination of mechanical strength and flexibility make PP ideal for 3D-printing. The low density of PP also means that lighter parts can be produced that are both strong and robust. The mechanical properties, the low density, and in addition the outstanding chemical resistance to substances such as acids, bases, alcohols or water makes PP ideally suited in a wide range of applications in different industrial sectors.

Automotive

PP is already an essential component in the automotive industry. 3D printing of PP can complement classic manufacturing processes such as injection molding or extrusion to optimize and further develop the application portfolio. PPprint sees the main potential of 3D printing with PP in the automotive industry in the rapid production of prototypes and development components to efficiently optimize products for series production. In this way, components can be manufactured in early development stages in the material that has a very similar property profile to the end-use material.

Exemplary uses:

Watertight Tanks, Air Ducts, Clips, …

Medical Technology

The material PP has proven its suitability for medical technology applications to the highest degree in the last decades. For applications as orthoses or orthopedic aids, the combination of break resistance, semi-flexibility, low density as well as the possibility of sterilization and easy cleaning is ideally suited for 3D printed PP products. As a result, individually manufactured PP products increase the wearing comfort and improve the healing process.

Exemplary applications:

Orthoses, positioning splints, connecting elements, individualized adaptation, standing or sitting assistance devices, …

Architecture, Art, and Fashion

3D printing is becoming increasingly important in today’s highly customized industries. Depending on the application, different properties of polypropylene, such as translucency or breaking strength, may be of interest. With polypropylene, there are no limits to the designer’s ability to create a highly customized part for real-world use.

Exemplary applications:

Break-resistant architectural models, lamps or illuminated elements, individualized decorative elements, …

Further industries

Polypropylene is by no means restricted to one specific industry or industrial sector. The balanced property profile can be beneficially used in manifold applications. If you are interested, please contact us for a free initial consultation for your specific application.

Further possible uses:

– Sport and Lifestyle

– Food Industry

– Filter Industry

– …