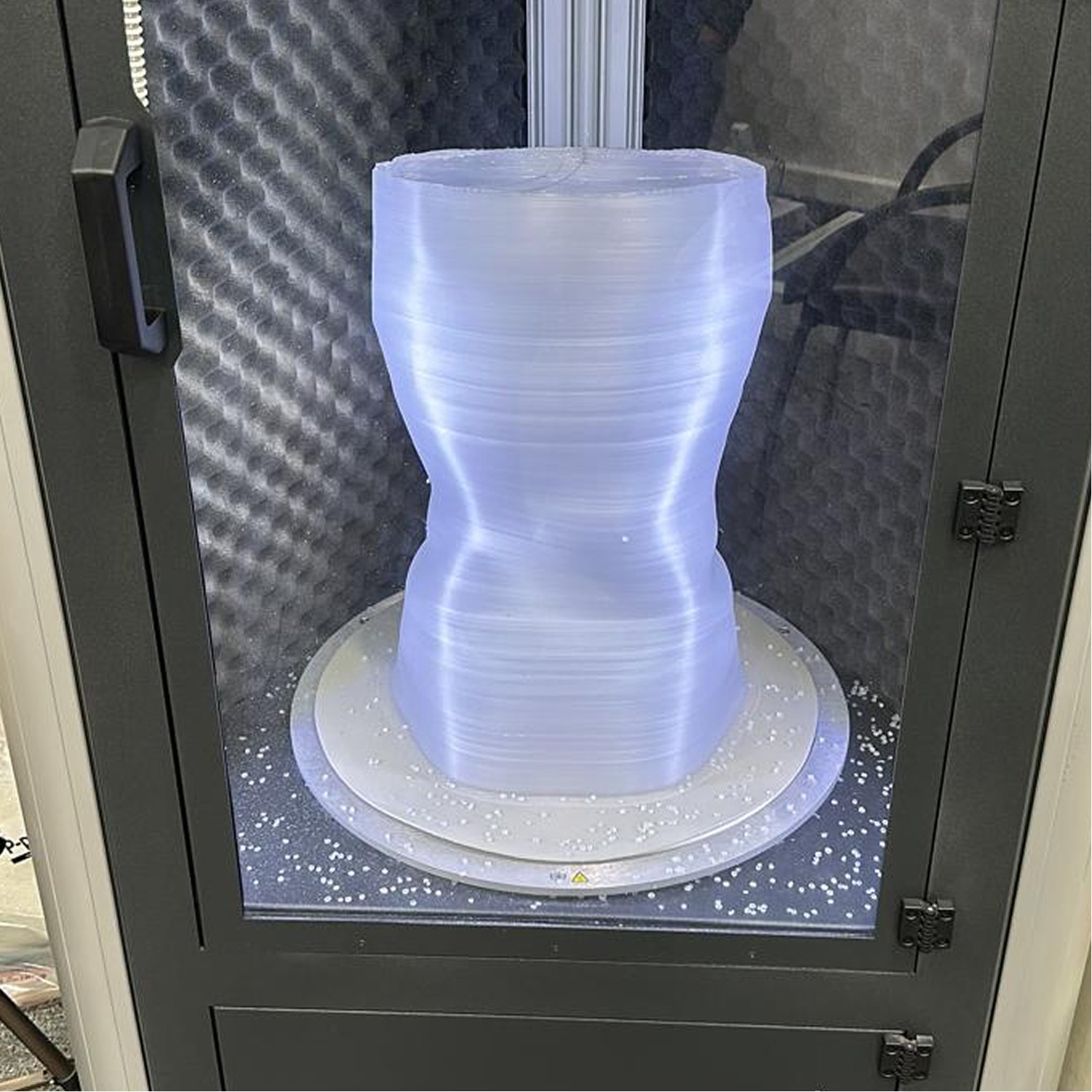

Nothing worked – until I discovered PPprint. From that moment, I knew I had found the right material.

Today, Antoine produces spinal orthoses with P-pellets 310 and insoles with P-filament 721 – proving how the right material can unlock new possibilities in orthotics and prosthetics.